Boron nitride nanotubes (BNNTs) are renowned for their outstanding physical and chemical properties, demonstrating tremendous potential in extreme environments, such as thermal management and space exploration. The nematic liquid crystal of BNNTs can be processed into aligned films and fibers, showcasing their capability for high-performance applications. Additionally, incorporating partially aligned BNNTs into composites through stretching methods shows notable advantages. However, the potential of planar-oriented BNNTs remains underutilized, primarily because the planar-oriented BNNTs obtained through post-processing only achieve partial alignment and exhibit increased defects. The direct synthesis of highly oriented, high-quality, horizontally aligned BNNTs would be an ideal solution to this challenge. However, there are few reports on synthesizing horizontally aligned BNNTs, and most horizontal alignments are achieved through carbon nanotube (CNT) template methods, which suffer from issues such as incomplete template removal and residual heteroatoms. Template-free direct growth of horizontally aligned BNNTs often results in superior quality, and its simplicity and efficiency make it a promising route for further harnessing the anisotropic properties of BNNTs. Chemical vapor deposition (CVD), due to its low growth temperature and robust controllability, is an attractive method for preparation. Despite considerable efforts, reports on template-free direct growth of high-quality, horizontally aligned BNNTs remain limited.

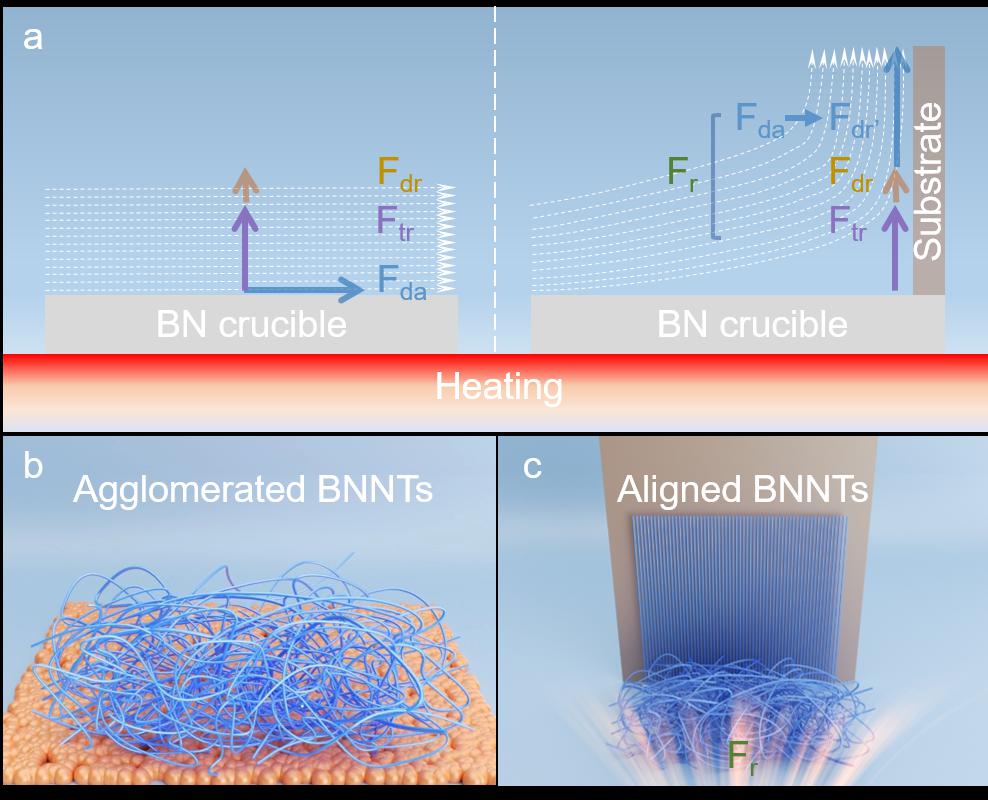

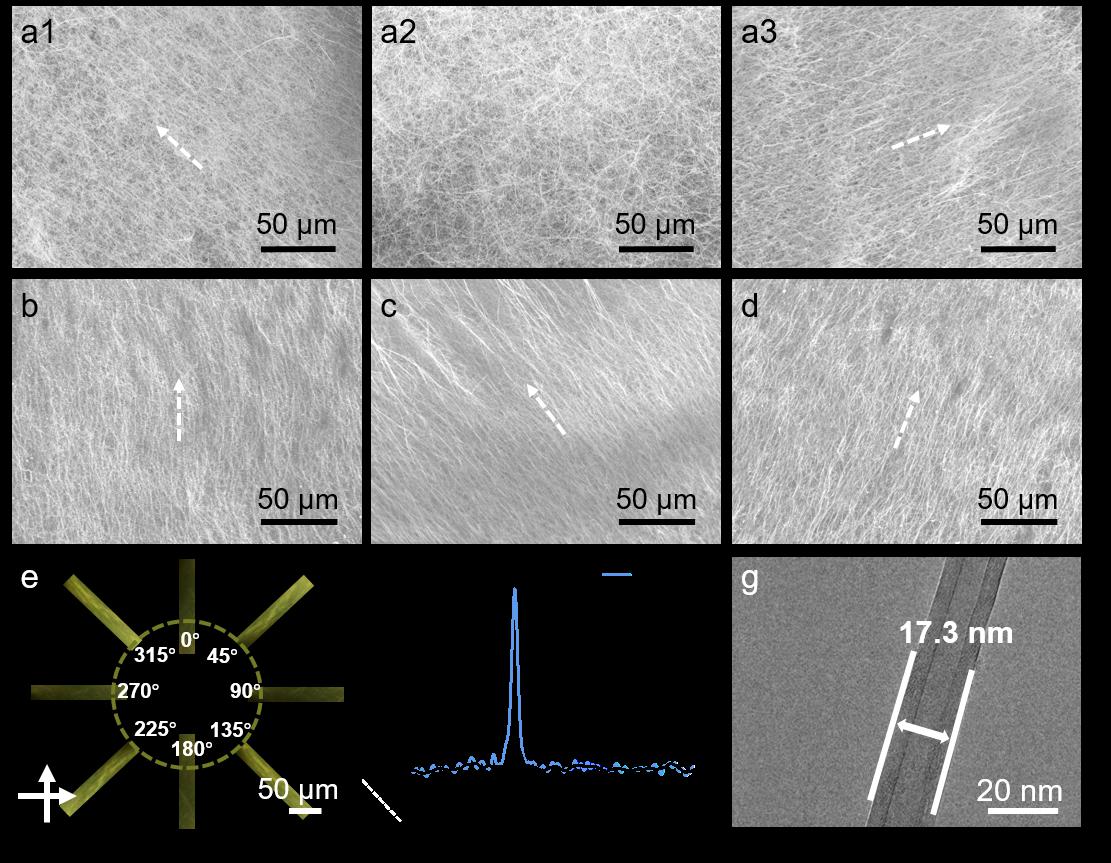

Based on this, Professor Yagang Yao’s team from Nanjing University proposed a “-surface-like growth” strategy to achieve high-quality, horizontally aligned BNNTs, drawing inspiration from the gasflow-directed growth method used for horizontally aligned CNT arrays. In the experiment, W2B5/Zn was used as a precursor, with the gasflow and precursor synergistically confining the floating of BNNTs near the precursor. By designing drag force and thermophoretic force, the BNNTs were aligned and collected on the substrate. Additionally, the alignment degree of horizontally aligned BNNTs could be controlled by adjusting the substrate to change the directional force. Experimental and computational fluid dynamics simulations indicated that the synergy of drag and thermophoretic forces facilitated the synthesis of horizontally oriented BNNTs. Moreover, this strategy was proven feasible with other catalyst systems, such as MoB2/Zn, further demonstrating its applicability and scalability. This study not only introduces a novel method for preparing horizontally aligned BNNTs but also holds significant potential to advance BNNT fabrication and application research.

Figure 1. Schematic of the growth of horizontally aligned boron nitride nanotubes (HABNNTs). (a) Analysis of forces at the bottom of the crucible before and after placing the substrate vertically. (b) BNNTs agglomerated through powder growth are confined near the precursor. (c) HABNNTs obtained on the surface of the vertically positioned substrate.

Figure 2. Characterization of products grown with W₂B₅/Zn. (a-d) SEM images of products on the substrate. (a1-a3) SEM images of products collected from different areas of substrate a. (e) Polarized optical microscopy image of the product. (f) Polarized Raman spectrum of the product. (g) Representative TEM image of the product, with an inset showing the HRTEM image of the tube walls.