With the rapid population growth and the increasingly serious water pollution, how to alleviate the pressure of water shortage and effectively treat wastewater has become an globally urgent problem. Many water treatment techniques have been developed to alleviate these problems, such as reverse osmosis membrane and ultrafiltration membrane techniques. However, by far there is no efficient and cost-effective method for treating highly concentrated brine (larger than 7% salinity) or wastewater. In terms of the widely used membrane treatment techniques, the treatment process of high-concentration brine and wastewater greatly damages the membrane. On the other hand, the concentration / crystallization methods consume a lot of energy. Therefore, looking for new efficient, stable, and cost-effective methods for treating high-concentration seawater and wastewater is one of the current topics of great concern. In recent years, due to its low carbon footprint, environmental protection and no requirements for extra energy input, the interfacial solar vaporgeneration provides new possibilities for seawater desalination and wastewater treatment. Nevertheless, in the process of treating highly concentrated brine and wastewater, the device shows serious fouling problems, which will seriously block the absorption of sunlight and hinder the sufficient supply of water, making the solar-to-vapor conversion efficiency decay rapidlyand even leading to device failure.

In response to this problem, Professor Prof. Jia Zhu's research group was inspired by the structure of water lilyand designed a Water-lily-inspired Hierarchical Structure (WHS) solar vapor generation device. When dealing with brine and 30 wt% wastewater, 80% solar-to-vapor conversion efficiency can be achieved. What's more worth mentioning is that in the process of treating highly concentrated brine and wastewater until the evaporation is complete (that is, zero discharge), the solar-to-vapor conversion efficiency showed no significant decrease, and the surface still remained clean. The manuscript titled asA Water-lily-inspired Hierarchical Design for Stable and Efficient Solar Evaporation of High Salinity Brine is published on Science Advances (DOI: 10.1126 / sciadv.aaw7013).

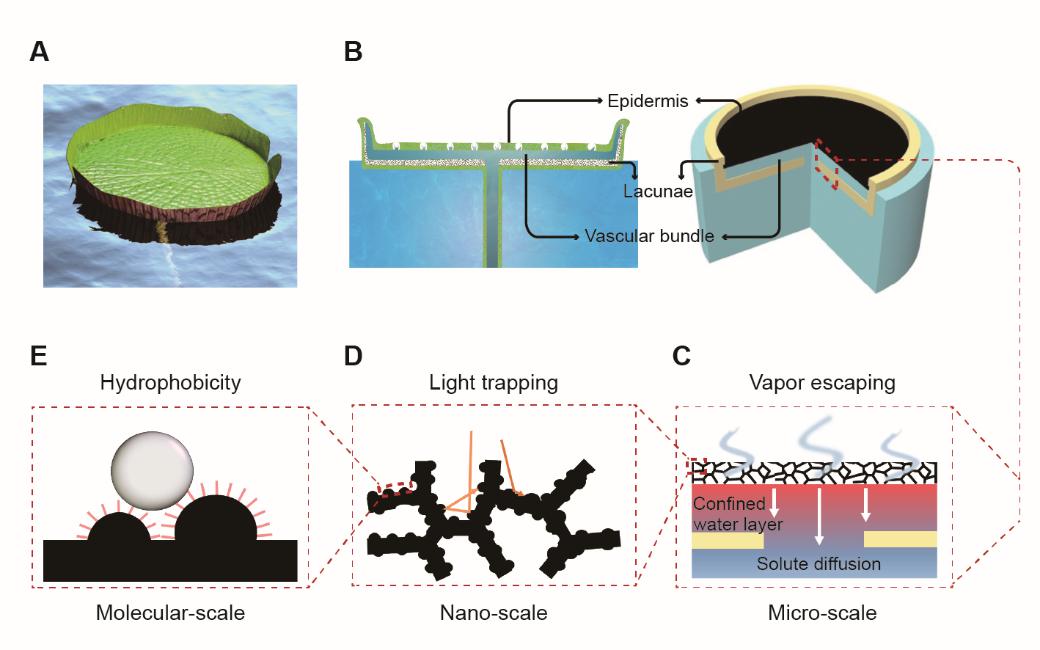

As can be seen in Fig 1A and B, water lily naturally has a very interesting structure. First of all, the epidermis can absorb sunlight, and there are plenty of stomata for water vapor escape. In the meanwhile,its well-known hydrophobic surface has self-cleaning property. Secondly, it can float naturally on the surface of water because of the existence of lacunae (air chamber) at the bottom of the leaf. Third, there exists a confined water path provided by vascular bundles to pump up water and then spread it into the large surface of the water lily.

Figure 1 Design concept of the water lily–inspired hierarchical structure (WHS).

(A and B) Water lily and water lily–inspired design for solar vapor generation, respectively. They share several key features: the upper epidermis with hydrophobic surface absorbs the sunlight and provides stomata for water vapor escape, lacunae (air chamber) at the bottom of the leaf keep a water lily afloat on the water, and vascular bundles (water path) provide a confined water supply and reduce heat conduction loss. (C) Microscale schematic of a confined water layer sandwiched between the hydrophobic top solar absorber and the bottom stand .(D) Nanoscale light trapping for the top solar absorber. (E) Molecular-scale surface modification for the hydrophobic surface of the top solar absorber.

The WHS device we designed consists of a top solar absorber and a bottom stand, which has similar characteristics with water lily (Fig. 1B). As is shown in Fig. 1C, the top solar absorber is similar to the epidermic of water lily with abundant micron pores, providing artificial “stomata” for continuous vapor escape. There are many nanoscalelight trappings on the surface of the absorber (Fig. 1D), which can effectively capture sunlight and endow the surface with the hydrophobic characteristics (1E). Mimicking the function of the lacunae (air chamber) of water lily, the researchers installed a polystyrene base with holes under the foamed copper, so that the entire device can float on the water. The polystyrene base has a very low thermal conductivity (<0.04 Wm-1K-1), which can suppress the diffusion of heat into the water. Finally. Finally, like the rhizomes of water lily, a quasi-one-dimensional channel (localized channel in the polystyrene base) is used for water supply.

When WHS devices treat brine and wastewater, water will enter through the holes in the base. Since the absorber on the top layer is hydrophobic on both sides, water will not enter the absorber, but will be sandwiched between the thin layer between the absorber and the base. This thin layer of water is the key to achieving stable and efficient treatment of concentrated brine. After the solar energy is absorbed and converted into heatby the absorber, it is localized in the thin water layer to realize a interfacial-typesolar-to-vapor conversion. At the same time, as evaporation occurs on the lower surface of the top absorber, when the water evaporates, salt and solute will not precipitate out on the upper surface, but will be excreted downwards and diffuse into the bottom water through the holes of the base.

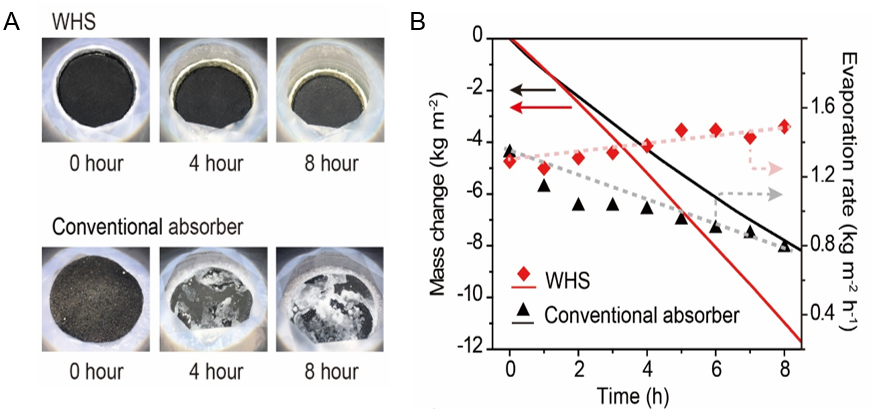

The research group conducted a performance test of the solar-to-vapor conversion of this WHS device. For pure water, 10 wt% brine, and 30 wt% wastewater, the WHS device showed a conversion efficiency of 79.8%, 78.5%, and 77.2%, and 1.31 kg m-2 h-1, 1.28 kg m-2 h- 1 and 1.27 kg m-2 h-1evaporation rate, respectively. While processing 10 wt% brine, the researchers made comparison with conventional absorbers. Under 1-sun illumination, using the WHS device for water treatment, the device surface remained clean (Fig.2A), and its evaporation rate had been maintained at a continuously high level (Fig. 2B). For conventional absorbers, salt gradually accumulated on the surface (Fig. 2A), which hindered the absorption of sunlight, so the evaporation rate gradually decreased (Fig. 2B). Under the same conditions, through calculations, the average evaporation rate of the WHS devicewithin 8 hours is 1.39 kg m-2 h-1, which was approximately 1.4 times higher than the average evaporation rate of conventional absorbers, 0.97 kg m-2 h-1.

Figure 2.Photographs A) and water evaporation rate curves B) of the WHS device and conventional absorber in the treatment of brine (initial concentration is 10 wt%).

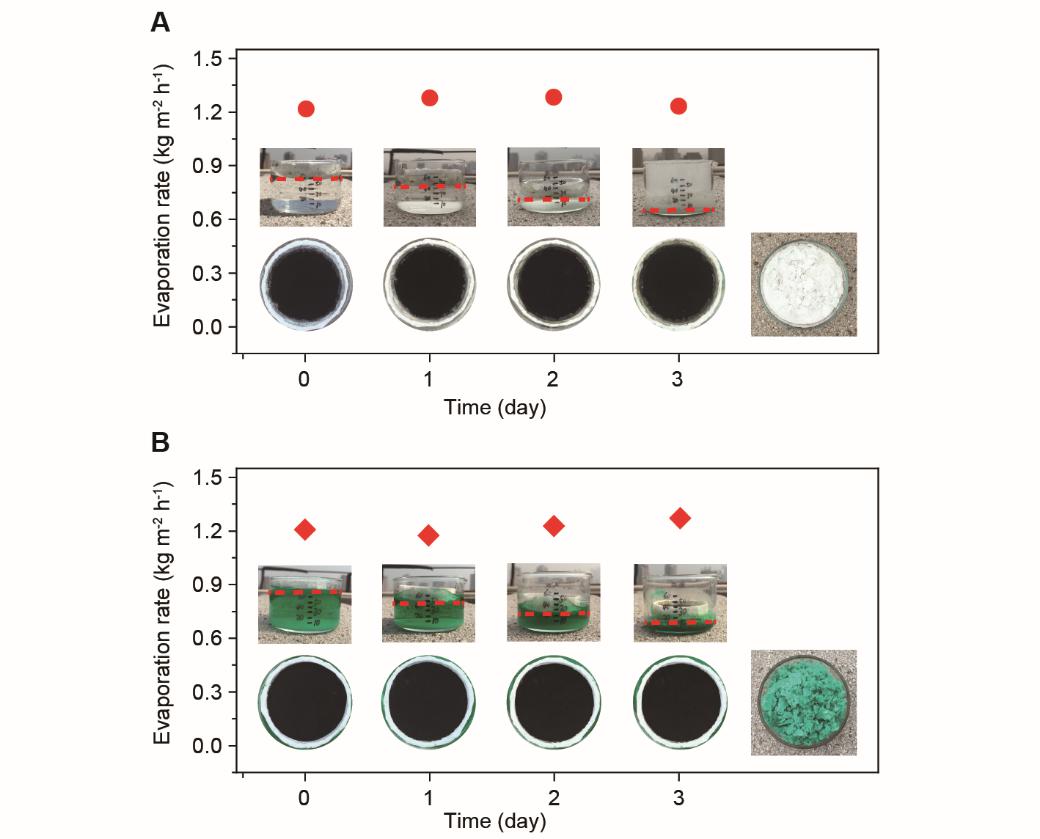

The WHS device can achieve complete separation of water and solute when treating brine or wastewater. As is shown in Fig. 3A and 3B, when the WHS device floated on the surface of the brine (wastewater), as the water gradually evaporated, the WHS device gradually moved down until the water was completely evaporated leaving salt or solute. It is worth mentioning that during this process, the WHS device showed a continuous and stable water evaporation rate, and there was no pollution on the surface (precipitation of salts or solutes). Photographs of the WHS device surface during this process are shown in the second column of illustrations in Fig. 3A and 3B. When the water was completely evaporated, the salt or solute left behind can be easily removed, as is shown in the lower right corner of Fig. 3A and 3B.

Figure 3. Complete separation of water and solute after stable and efficient solar evaporation.

(A and B) Evaporation rates of each day for solar desalination and wastewater treatment, respectively. The first and second lines of the insets are the side view and top view of the sample during daily work. The rightmost column is the salt and metal solute samples collected after complete water-solute separation.

Grade 14 graduate Ning Xu and Grade 16 graduate Jinlei Li of Prof. Jia Zhu’s research group are joint first authors. Prof Jia Zhu of College of Engineering and Applied Science is the corresponding author. This work also received guidance and support from Academician Shining Zhu of Nanjing University. This research is supported by the National Laboratory of Solid State Microstructures, the National Key R & D Program of China, the National Natural Science Foundation of China, and the Fundamental Research Funds for the Central Universities.